当您需要半导体工具设置和维护过程中最高效和有效的测量设备时, count on lol菠菜软件, 无线半导体腔隙测量设备的全球市场领导者, leveling, wafer handoff teaching, vibration, airborne particle, relative humidity and resistance measurement.

Semiconductor fabs and OEMs value the accuracy, WaferSense和ReticleSense测量产品组合的精度和多功能性,可提高晶圆厂产量和设备正常运行时间.

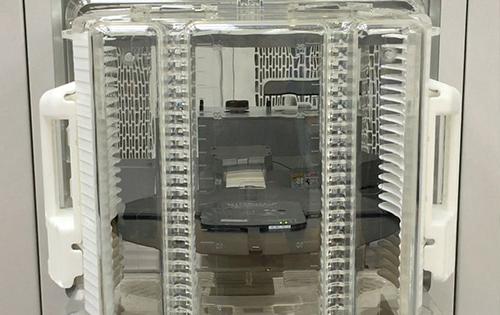

Since the wireless, 支持蓝牙®和电池供电的设备呈晶圆状或十字形, they can generally travel anywhere a wafer or reticle travels, 提供最佳的易用性和访问位置,否则可能很难或不可能到达.

校准可以在封闭的过程条件下与真空兼容的WaferSense和ReticleSense测量设备进行.

接收和记录数据实时在您的笔记本电脑与lol菠菜软件易于使用的软件,并指望准确, precise, 与传统或遗留方法相比,可靠且可重复的结果节省了时间和费用.

CyberSpectrum是一个功能强大但非常简单的软件,具有直观的界面,为多种应用的实时测量和分析提供数字和视觉反馈.

WaferSense软件开发工具包为WaferSense®和ReticleSense®系列设备提供应用程序编程接口(API). 这允许将设备直接集成到用户开发的软件应用程序中.